|

|

Cat® BDP1000 Bi-Directional Power Inverter

|

Engine Paralleling and Integration Control (EPIC)

|

|

EMCP 4.4 Master Control Panel

|

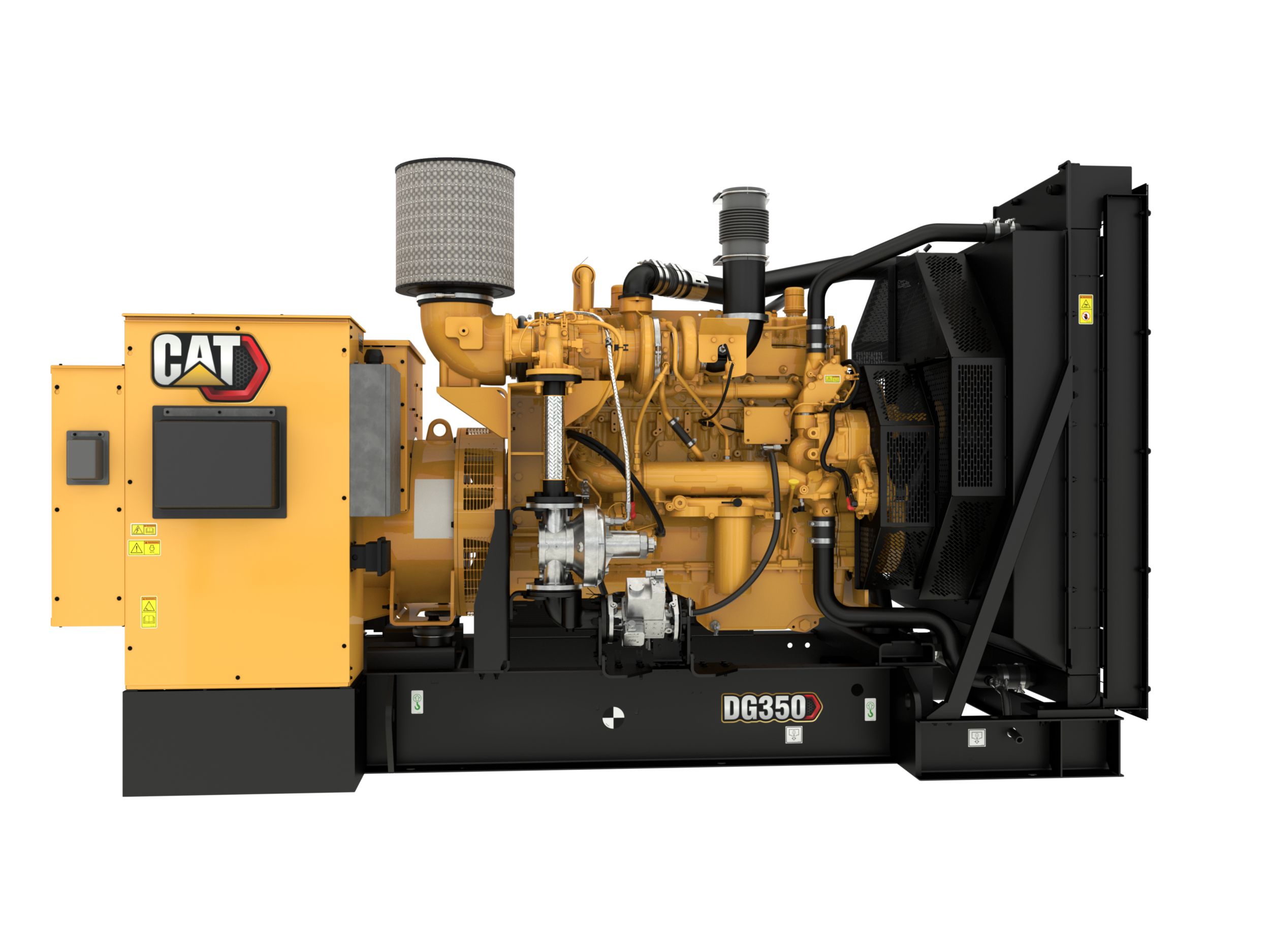

Generator Set Specifications |

| Frequency |

60 Hz |

- |

- |

- |

- |

| Natural Gas Rating |

350 ekW |

- |

- |

- |

- |

| Emissions/Fuel Strategy |

U.S. EPA Certified for Stationary Emergency Application and Non-Emergency Applications |

- |

- |

- |

- |

| Fuel Type |

Natural Gas |

- |

- |

- |

- |

| RPM |

1800 |

- |

- |

- |

- |

| Voltage |

208 - 600 VAC |

- |

- |

- |

- |

Engine Specifications |

| Engine Model |

Cat® CG18 In-line 6, 4-cycle Natural

Gas |

- |

- |

- |

- |

| Fuel System |

Gas mixer, Venturi |

- |

- |

- |

- |

| Aspiration |

Turbocharged - Air-to-Air Aftercooled |

- |

- |

- |

- |

| Governor Type |

Electronic |

- |

- |

- |

- |

| Displacement |

1106.3 in³ |

- |

- |

- |

- |

| Compression Ratio |

10.5:1 |

- |

- |

- |

- |

| Bore |

5.7 in |

- |

- |

- |

- |

| Stroke |

7.2 in |

- |

- |

- |

- |

Generator Set Dimensions |

| Length |

154 in |

- |

- |

- |

- |

| Width |

73 in |

- |

- |

- |

- |

| Height |

82 in |

- |

- |

- |

- |

| Weight |

10721 lb |

- |

- |

- |

- |

Technical Summary |

| Application |

- |

Energy Storage System |

LV and MV (208V-27kV) |

LV and MV ( 208V - 38 kV |

LV and MV (208V - 38 kV) |

| Module Type |

- |

Integral part of Power Grid Stabilization and Energy Time Shift modules |

- |

- |

- |

| Rated Power |

- |

1000 kVA (1000kW 1PF) |

- |

- |

- |

| Configuration |

- |

- |

Remote modular paralleling control system (Master Control Panel for the first 2 generator sets and optional tie breaker, separate add-on control panels for up to 8 additional generator sets, utility paralleling control, and distribution control) |

Configurable PLC based switchgear capable of controlling and monitoring multiple generator sets, tie, utility and load breakers for utility paralleling applications |

Remote monitoring and control for up to 8 generator sets via high-speed network. Enables paralleling a group of EMCP 4.4 equipped generator sets to a single utility source. |

| Modes of Operation |

- |

- |

Emergency Standby with redundant master control, Utility paralleling, peak shaving, and closed transition to/from Generator Power (with optional utility control panel) |

Emergency Standby, Utility Import/Export, Peak shaving, and base load operations with redundant controls and components. Closed transition to/from generator power |

Emergency standby, island, utility paralleling |

Generator Protective Devices |

| ANSI Protective Devices |

- |

- |

15/25. 27/59, 81 O/U, 32, 40, 90 (Industrial Grade) |

15/25, 27/59, 81 O/U, 32, 40, 50, 51 |

15/25, 27/59, 81 O/U, 32, 40, 50, 51 |

Utility Protective Devices |

| ANSI Protective Devices |

- |

- |

15/25. 27/59, 81 O/U, 32,47 (Industrial Grade) |

15/25, 27/59, 81 O/U, 32, 40, 47, 50, 51, 86 |

15/25. 27/59, 81 O/U, 32,47 (Industrial Grade) |

Environmental Parameters |

| Certifications |

- |

- |

UL / cUL 508A |

IBS, CBC, UBC & OSHPD Certified |

IBC, CBC, UBC & OSHPD Certified |

| Control Panel Enclosure |

- |

- |

NEMA 12 |

NEMA 1 or NEMA 3R, Freestanding Construction |

NEMA 1 wall-mounted construction |

| Operating Temperature |

- |

- |

0°C to 55°C |

0 degrees to 50 degrees C |

0°C to 50°C |

| Storage Temperature |

- |

- |

-20°C to 60°C |

-20 degrees C to +60 degrees C |

-20°C to +60°C |

| Low Voltage Standards |

- |

- |

- |

NEMA SG-5, CSA, ANSI C37.51, ANSI C37.20.1, UL 1558 or UL 891, NFPA 110, NFPA 99 and NFPA 70 |

NEMA SG-5, CSA, ANSI C37.51, ANSI C37.20.1, UL 1558 or UL 891, NFPA 110, NFPA 99 and NFPA 70 |

| Medium Voltage Standards |

- |

- |

- |

NEMA SG-5, ANSI / IEEE C37.20.2, CSA-C22.2 No. 31-M89, EEMAC G8-3.2, NFPA 70, NFPA 99 and NFPA 1110 |

NEMA SG-5, ANSI / IEEE C37.20.2, CSA-C22.2 No. 31-M89, EEMAC G8-3.2, NFPA 70, NFPA 99 and NFPA 1110 |