|

|

Cat® BDP1000 Bi-Directional Power Inverter

|

Engine Paralleling and Integration Control (EPIC)

|

EMCP 4.4 Master Control Panel

|

Cat Customizable Switchgear and Controls

|

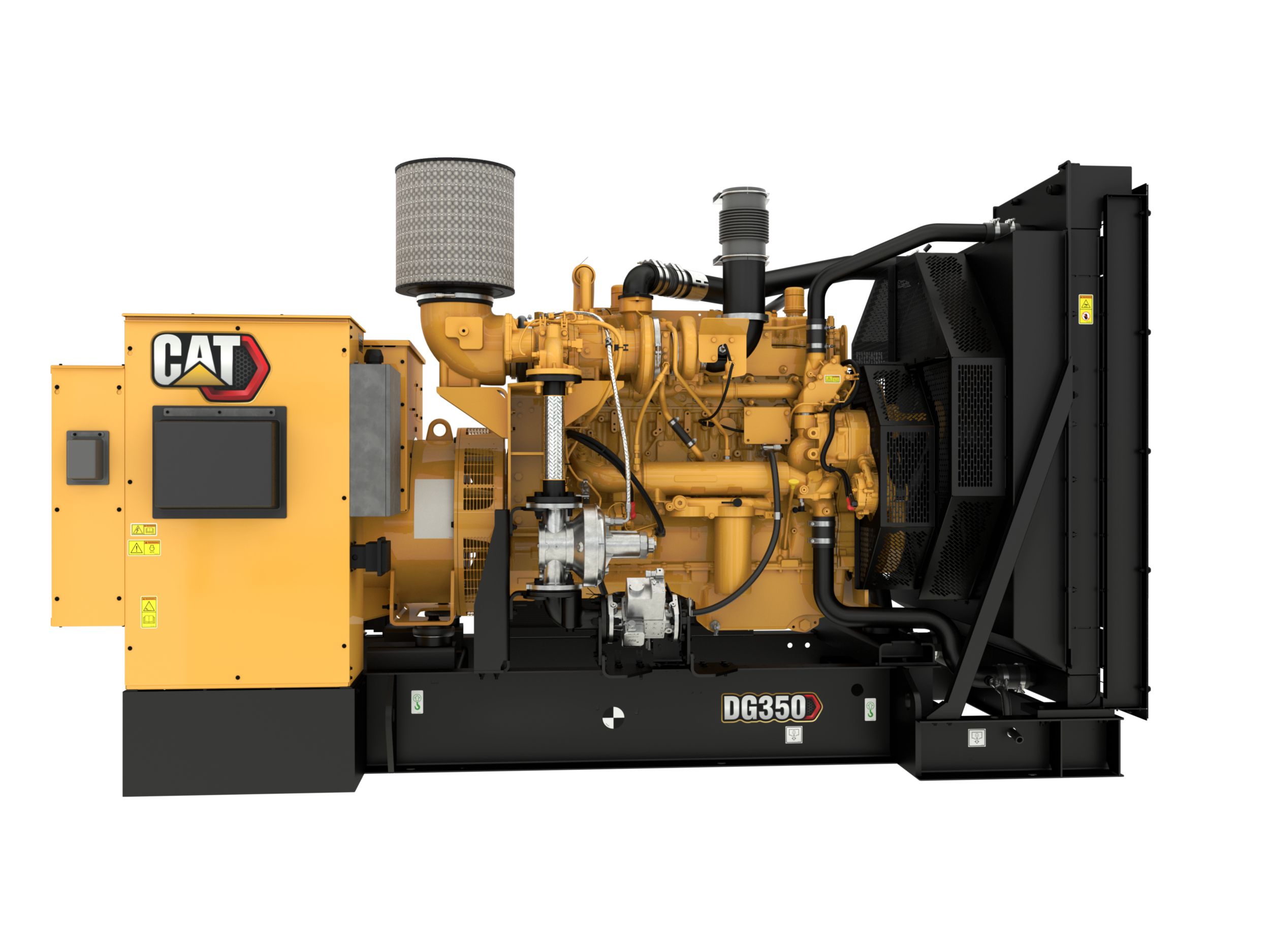

Generator Set Specifications |

| Frequency |

60 Hz |

- |

- |

- |

- |

| Natural Gas Rating |

350 ekW |

- |

- |

- |

- |

| Emissions/Fuel Strategy |

U.S. EPA Certified for Stationary Emergency Application and Non-Emergency Applications |

- |

- |

- |

- |

| Fuel Type |

Natural Gas |

- |

- |

- |

- |

| RPM |

1800 |

- |

- |

- |

- |

| Voltage |

208 - 600 VAC |

- |

- |

- |

- |

Engine Specifications |

| Engine Model |

Cat® CG18 In-line 6, 4-cycle Natural

Gas |

- |

- |

- |

- |

| Fuel System |

Gas mixer, Venturi |

- |

- |

- |

- |

| Aspiration |

Turbocharged - Air-to-Air Aftercooled |

- |

- |

- |

- |

| Governor Type |

Electronic |

- |

- |

- |

- |

| Displacement |

1106.3 in³ |

- |

- |

- |

- |

| Compression Ratio |

10.5:1 |

- |

- |

- |

- |

| Bore |

5.7 in |

- |

- |

- |

- |

| Stroke |

7.2 in |

- |

- |

- |

- |

Generator Set Dimensions |

| Length |

154 in |

- |

- |

- |

- |

| Width |

73 in |

- |

- |

- |

- |

| Height |

82 in |

- |

- |

- |

- |

| Weight |

10721 lb |

- |

- |

- |

- |

Technical Summary |

| Application |

- |

Energy Storage System |

LV and MV (208V-27kV) |

LV and MV (208V - 38 kV) |

LV and MV ( 208V - 38 kV) 50 / 60 Hz |

| Module Type |

- |

Integral part of Power Grid Stabilization and Energy Time Shift modules |

- |

- |

- |

| Rated Power |

- |

1000 kVA (1000kW 1PF) |

- |

- |

- |

| Configuration |

- |

- |

Remote modular paralleling control system (Master Control Panel for the first 2 generator sets and optional tie breaker, separate add-on control panels for up to 8 additional generator sets, utility paralleling control, and distribution control) |

Remote monitoring and control for up to 8 generator sets via high-speed network. Enables paralleling a group of EMCP 4.4 equipped generator sets to a single utility source. |

Application-specific switchgear with control logic designed to meet any customer's sequence of operations. Examples are 3+ Utilities, CHP applications, complex load shed schemes, etc |

| Modes of Operation |

- |

- |

Emergency Standby with redundant master control, Utility paralleling, peak shaving, and closed transition to/from Generator Power (with optional utility control panel) |

Emergency standby, island, utility paralleling |

All modes of paralleling generator sets to each other and to other sources (utility, alternative fuels, wind, etc) can be supported. Caterpillar generation and control experts can design and program the most complex power schemes to meet your critical pow |

Generator Protective Devices |

| ANSI Protective Devices |

- |

- |

15/25. 27/59, 81 O/U, 32, 40, 90 (Industrial Grade) |

15/25, 27/59, 81 O/U, 32, 40, 50, 51 |

Per customer specification |

Utility Protective Devices |

| ANSI Protective Devices |

- |

- |

15/25. 27/59, 81 O/U, 32,47 (Industrial Grade) |

15/25. 27/59, 81 O/U, 32,47 (Industrial Grade) |

Per customer specification |

Environmental Parameters |

| Certifications |

- |

- |

UL / cUL 508A |

IBC, CBC, UBC & OSHPD Certified |

Per customer specification |

| Control Panel Enclosure |

- |

- |

NEMA 12 |

NEMA 1 wall-mounted construction |

Per customer specification |

| Operating Temperature |

- |

- |

0°C to 55°C |

0°C to 50°C |

Per customer specification |

| Storage Temperature |

- |

- |

-20°C to 60°C |

-20°C to +60°C |

Per customer specification |

| Low Voltage Standards |

- |

- |

- |

NEMA SG-5, CSA, ANSI C37.51, ANSI C37.20.1, UL 1558 or UL 891, NFPA 110, NFPA 99 and NFPA 70 |

Per customer specification |

| Medium Voltage Standards |

- |

- |

- |

NEMA SG-5, ANSI / IEEE C37.20.2, CSA-C22.2 No. 31-M89, EEMAC G8-3.2, NFPA 70, NFPA 99 and NFPA 1110 |

Per customer specification |