Job safety is more than just a concept. It takes every person on the job site staying alert – actively watching for and eliminating potential hazards.

The need for constant vigilance is made a little easier with Cat® technology. Technological solutions for identifying common safety issues are helping make construction safer.

The Importance of Construction Site Safety

Construction sites are inherently full of risk. A busy job site is loud and fast-paced, with big machines and people moving back and forth. It can be easy to end up getting injured – or worse.

Urban construction sites can be dangerous to more than just those at work – the general public is also at risk of accidents. Following strict safety protocols protects passersby from being hurt by falling objects and other preventable incidents.

The key to any construction site safety program is a strong safety culture. That culture involves every aspect of worker safety, from training to inspection to feedback. You can create a strong safety culture by:

- Providing regular training sessions for all employees.

- Encouraging employees to speak up when they notice something is wrong.

- Frequently inspecting the site for hazards.

- Ensuring the proper personal protective equipment (PPE) is available and accessible.

As a leader, demonstrating that you take your workplace’s safety rules seriously can inspire your employees to participate more fully in your safety culture, leading to reduced risks and increased safety over time.

5 Benefits of Construction Safety Technology

Safety goes beyond helping your employees. Using technology to increase safety on your construction site can also help your organization as a whole.

These five benefits demonstrate the importance of technology in the construction industry:

1. Reduced Risk of On-Site Injuries

Perhaps the most obvious result of investing in safety technology is a lower rate of on-site injuries.

Management officials should always lead by example. It’s important to demonstrate your enthusiasm for your safety culture consistently. The more you show you care about your safety culture, the more likely your employees are to participate, and the safer your sites will be.

2. Increased Return on Investment

Implementing and practicing safety measures can also benefit your organization financially. For example, with fewer on-site injuries, you’ll be able to save money you would otherwise have spent on workers’ compensation costs and hospital bills.

Plus, higher productivity rates make meeting project deadlines easier, which in turn makes it easier to ensure you get paid in full upon completion.

3. Improved Staff Retention

In general, employees prefer workplace well-being to perks or other material benefits. Employees who feel like their managers care about their safety and well-being are far more likely to stick around. Building a strong safety culture that encourages full participation from all levels of the organization is invaluable to employee retention.

Investing in safety can also give contractors an edge in recruiting new hires. According to OSHA, workplace safety is one of the top criteria workers consider when evaluating new job offers. Employers who prioritize safety measures might find it easier to bring on new team members.

4. Enhanced Public Reputation

Investing in safety programming can make your organization more trustworthy to stakeholders and the general public.

Thoroughly documenting safety records is a good way to start building this reputation. Gather information from your employees, machines, and data-collecting technology into a digital management system to simplify this record-keeping process.

Make sure you document everything, even serious incidents. Transparency goes a long way in building your reputation, as long as you take the proper steps to fix the problem. This demonstrates your organization’s commitment to safety.

5. Consistent Compliance With Safety Standards

Whether your organization is trying to gain a specific certification or just needs to comply with OSHA standards, meeting safety requirements is crucial to any company’s success.

Violations are costly and often damaging to businesses. For context, a first-time OSHA violation will cost you $13,653, and repeated violations can cost $136,532 per incident.

Thankfully, advanced safety technology can help you meet standards more easily. By using technological solutions to inspect your site, collect data, or even automate certain processes, you can ensure your site is up to code.

What Technology Is Used in Construction?

Many types of construction technology can help boost an organization’s safety score. Data collection and analysis tools are beneficial for site managers who want to know the best solutions for their equipment.

Here are some common examples of new construction technology trends:

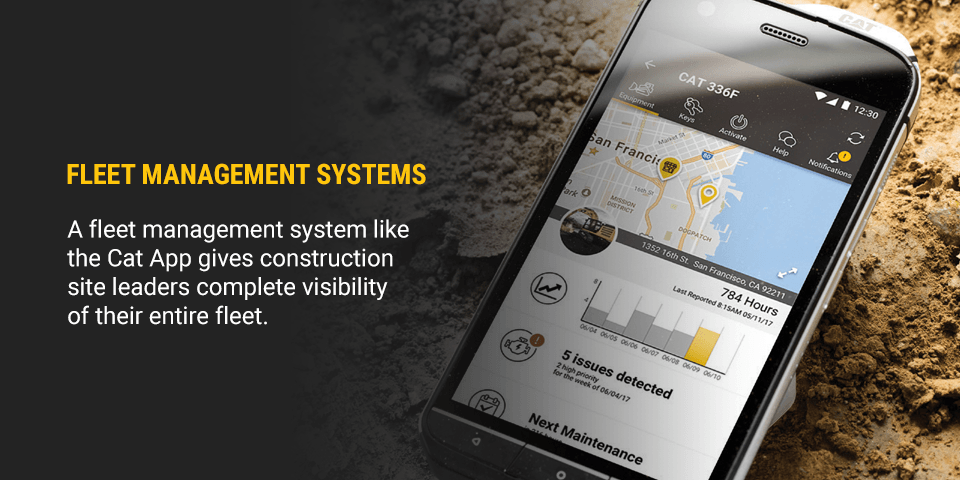

- Fleet management systems: A fleet management system like the Cat App gives construction site leaders complete visibility of their entire fleet. Using one of these programs allows you to monitor the status and location of every machine in action, order parts and services, and even remotely start newer machines all from one app. This way, you can keep up-to-date on maintenance before problems arise with any of your machines.

- Artificial intelligence (AI): AI programs can make safety evaluations easier for site managers by performing rapid analysis of on-site risks and suggesting plans to mitigate those risks. This kind of technology is especially helpful for creating comprehensive preventive safety procedures.

- Drones: Drones are emerging in the construction industry as an easy way to inspect a site for hazards before work begins. By surveying the site from the air, a drone can find risks more efficiently – and more safely – than human inspectors could in the same amount of time.

- 3D printing: 3D printing is becoming increasingly commonplace on construction sites. Users can program 3D printers to create walls, complex decorative elements, or even concrete much quicker than humans would take to build the same thing. 3D printers also cut down on physical labor, which prevents workers from becoming fatigued and engaging in risky behaviors as a result.

- Robotics and automation: Robotic elements are still relatively uncommon on the construction scene due to their high price tag and controversial nature. However, as the technology becomes more affordable, construction companies are recognizing its benefits. Automated and robotic machines take some of the physical demands off workers, decreasing the risk of fatigue and boosting productivity by freeing employees to concentrate on other tasks.

Cat Technology for Construction Safety

At Caterpillar, we make safety a priority. From providing ongoing safety training programs to integrating intelligent solutions into our equipment, we aim to help you meet your safety goals – and even exceed them – while staying within your budget.

As part of our ongoing dedication to safety, Cat has developed several solutions to help both construction workers and site managers enhance safety on their job sites.

Cat Command

Cat Command allows operators to control their equipment remotely using either a computer or a special controller. It’s most useful for dozing, loading, compacting, excavating applications, or any job that requires driving on potentially dangerous terrain. It provides operators with a clearer sightline than they would have from the cab of a vehicle on-site and increases productivity as a result of increased operator comfort.

With the flexibility of Cat Command, you can keep your employees out of dangerous situations, significantly reducing your operation’s risk of injury. You can also control multiple machines simultaneously, which keeps productivity high.

Cat Detect

With Cat Detect, heavy equipment operators are more aware of their surroundings, preventing worker injuries and damage to equipment. The technology works by using a system of cameras and proximity sensors to detect movement and increase operator awareness of their environment.

Cat Detect is available in several different forms that help to ensure safe use of machinery across all applications:

- 2D E-fences: Cat Detect’s 2D electric fences (e-fences) limit excavator movement in tight spaces based on the information it receives from the sensors. Once it senses something nearby, the e-fence automatically stops the machine from moving further, keeping the operator and nearby workers safe.

- Object Detection: The object detection system uses a combination of radar and camera systems to alert operators about moving objects within the machine’s immediate vicinity. This technology is available for any machine and can enhance safety throughout your whole site.

- Rear Object Detection: This two-part system is meant specifically for wheel loaders. It uses a radar system to alert operators when moving objects enter the machine’s immediate vicinity. Additionally, the operator can see behind their machine when reversing thanks to in-cab cameras.

- Underground: Cat Detect for Underground gives operators night vision. It works through a peer-to-peer proximity detection system combined with a communications and tracking network to alert operators of nearby objects or people.

Cat Compact

Cat Compact provides compactor operators with in-the-cab feedback that outlines what work they have left to do to meet project specifications. Operators can utilize this technology to help make their navigation more precise, preventing the machine from tipping over and potentially resulting in serious injuries. It’s useful for multiple situations, such as site prep, landfill work, and road paving.

Additionally, the data collected can help supervisors learn operators’ behavior patterns, which can be used to help correct repeated unsafe behaviors.

Cat Payload

Cat Payload is an onboard weighing system that allows project managers to monitor the location and status of their teams’ supplies.

It works by collecting data about what, where, and how much material an operator loads on their machine at any given time. It’s compatible with multiple machines, from off-road haulers to wheel loaders, and is a standard feature on Next Generation excavators and wheel loaders.

Additionally, Cat Payload allows operators to keep track of how much material they’re lifting at any given time through the in-cab display. This way, operators can better ensure they’re staying within lift and load capacities.

Cat Driver Safety System

Built into a machine’s enclosed cab, the Cat Driver Safety System (DSS) monitors an operator’s eye and head movements to determine whether they are distracted or fatigued. If the system receives input that suggests the operator is distracted or nodding off, it does the following:

- Alarm: An alarm sounds within the cab, alerting the driver to restore their attention.

- Vibration: The seat will vibrate to get the driver’s attention.

- Alert: After the alarm sounds, the system will alert a site supervisor to check on the employee.

This three-step alert helps to warn fatigued operators and their supervisors and to prevent potentially unsafe operation.

Cat Smartband

Speaking of fatigue, Cat’s wearable fatigue detection system, the Cat Smartband, uses data to predict whether an employee has received enough rest before operating a machine. The program can even predict how many hours an employee will be able to work before needing to rest. It works like this:

- The Smartband collects data on the amount of sleep an employee gets, their Circadian rhythms, and other information.

- Upon arrival at the job site, the system assigns the worker a fatigue score and combines it with the scores of other users to create a report for supervisors.

- A score below 70 indicates dangerous fatigue levels – this degree of exhaustion is enough to cause behaviors and reaction times that resemble intoxication.

You can even combine the Smartband with a DSS to create your own comprehensive safety solution.

Virtual Reality Training

Effective training is key to building a strong safety culture for any job site. Hands-on or active learning has been proven to cause higher learning and retention than traditional lecture-style training sessions. Essentially, students who get the chance to work through problems actively can remember more information for longer.

Caterpillar Safety Services has developed virtual reality (VR) training technology to provide an engaging, interactive method of learning important safety behaviors. This training applies to both employees and supervisors.

The VR headset drops learners into a bustling job site where they have to work through a sequence of different industry-relevant scenarios. This kind of training experience allows employees to learn within a safe environment.

Choose Cashman Equipment for Your Construction Technology Needs

At Cashman Equipment, we’re dedicated to providing you with the tools to create a safe and productive workplace. We have a wide range of Cat heavy equipment and technology for the construction industry as well as for mining and earthmoving applications.

You can contact us online for more information or call us at 800-937-2326 to speak with a representative.

Looking for equipment? Find a location near you.